Where Have You Been?

The short answer is "around", but the real answer is more

complicated. Due to :gestures at world:, I haven't really been

mentally in a place where I can spend time working on things like

this project. After a few months of just zoning out, I've realized I

need the structure of a project to keep me focused, and so I'm

trying to pick back up where I left off.

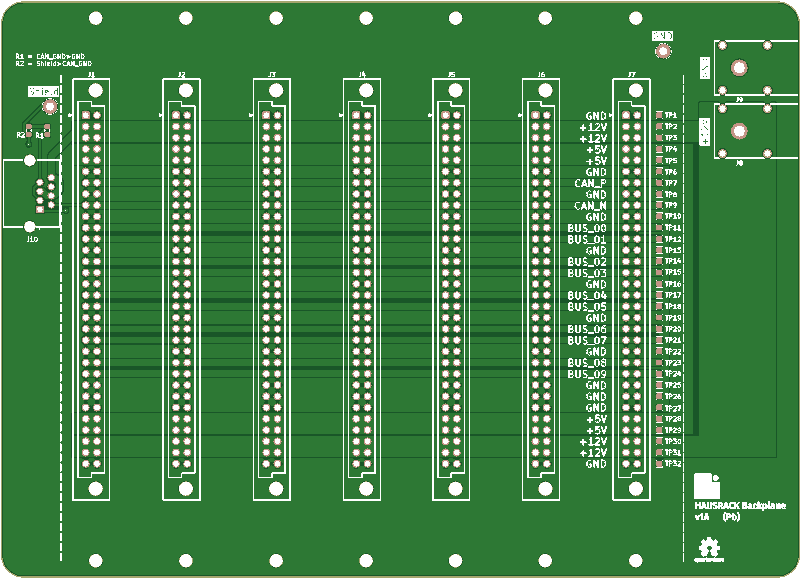

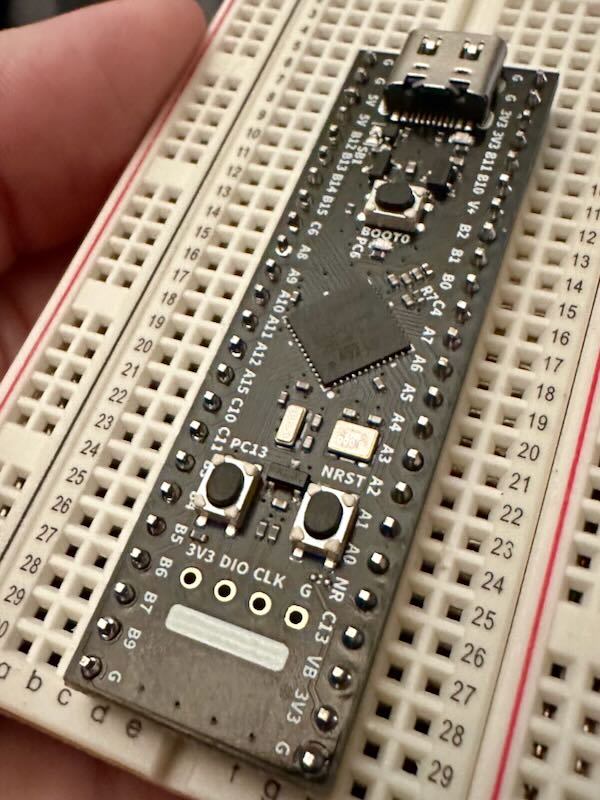

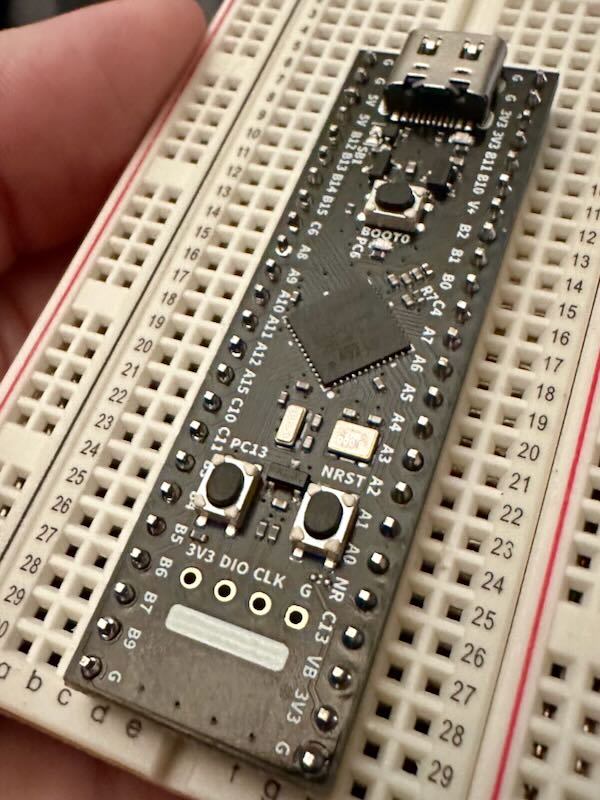

When last we talked, I was talking about a modular base board built

around an STM32H5, but I realized that there was another alternative ...

build it around an existing board. So, that's my plan now. This removes

a lot of design work, yes, but at least for the initial design, it lets

me focus on some other things. I've chosen to use a board from WeAct

Studio. These are the people behind the famous Blue Pill and Black Pill

STM32 boards. They also make one built around an

STM32G474CEU6,

which is a 170MHz ARM Cortex-M4 with 128KB of RAM, 512KB of Flash, and

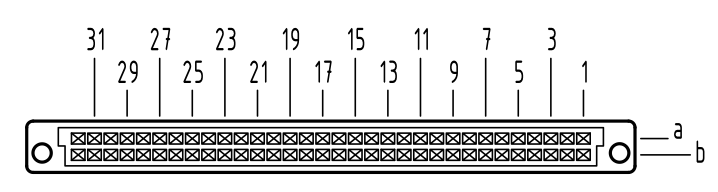

2 CAN-FD buses available. It's in a somewhat long 48-pin package. If you

want to buy one, you can find them on your neighborhood massive Chinese

marketplace.

When last we talked, I was talking about a modular base board built

around an STM32H5, but I realized that there was another alternative ...

build it around an existing board. So, that's my plan now. This removes

a lot of design work, yes, but at least for the initial design, it lets

me focus on some other things. I've chosen to use a board from WeAct

Studio. These are the people behind the famous Blue Pill and Black Pill

STM32 boards. They also make one built around an

STM32G474CEU6,

which is a 170MHz ARM Cortex-M4 with 128KB of RAM, 512KB of Flash, and

2 CAN-FD buses available. It's in a somewhat long 48-pin package. If you

want to buy one, you can find them on your neighborhood massive Chinese

marketplace.

Since I'm planning to write all the software on top of

Zephyr, and this board isn't in their

already extensive list of

boards, I

needed to add it to that. So, into the breach we go.

First, I read the

documentation.

Since the SOC is supported already thanks to a ton of work from

STMicroelectronics, it really just meant customizing for this specific

instance on this board. To do that, I needed to name the board, and then

create a bunch of files. The name I chose was stm32g474_long under the

weact

vendor

directory. Those files are:

board.yml-

a YAML file describing the high-level meta data of the boards such

as the boards names and the SOC.

weact_stm32h474_long.dts-

The hardware description in devicetree format. This declares your SOC,

connectors, and any other hardware components such as LEDs, buttons,

sensors, or communication peripherals (USB, etc).

Kconfig.weact_stm32h474_long-

This is the base software configuration for selecting SOC and other

board and SOC related settings. Kconfig settings outside of the

board and SOC tree must not be selected. To select general Zephyr

Kconfig settings the Kconfig file must be used.

board.cmake-

Provides information on flashing and debugging the board

weact_stm32h474_long.yaml-

A bunch of metadata that's mostly used by the test runner to help

understand what tests to run. Note, I don't know why this one ends

in yaml, but the other in yml, nor whether it matters, but I

just copied the style in the documentation.

weact_stm32h474_long_defconfig-

Some Kconfig-style presets for building any application. These can

be overridden in the application.

Rather than start from a clean slate, I actually decided to "borrow"

some of the already made board configs from an existing WeAct board, the

STM32G431

model. This gave me a good head start on what I needed to do.

So let's go through the files. I hope my explanations are both

reasonably accurate and passably consumable. I'm learning this as I go

along, and so this is just my current knowledge.

| board:

name: weact_stm32g474_long

vendor: weact

socs:

- name: stm32g474xx

|

This is pretty obvious, but the name of the SOC (line 5) is something

you have to find in the existing

repository.

Some of the naming isn't necessarily obvious to me, but it was pretty

easy to figure out. Once you get to the right processor

family

it's not too bad.

This is the biggest of all of them, so let's take it from the top (post

copyright). First, this is a

devicetree

format, which is also used Linux. I can't say as I consider myself to

know it yet, but I've started to get a feel for it. I've elided empty

lines along the way.

| /dts-v1/;

#include <st/g4/stm32g474Xe.dtsi>

#include <st/g4/stm32g474r(b-c-e)tx-pinctrl.dtsi>

#include <zephyr/dt-bindings/input/input-event-codes.h>

|

First, we set the version of the DTS (devicetree) schema that's in use,

then we include some existing files to set up some presets.

12

13

14

15

16

17

18

19

20

21

22

23 | / {

model = "WeAct STM32G474CEU6 Long board";

compatible = "weact,stm32g474_long";

chosen {

zephyr,console = &lpuart1;

zephyr,shell-uart = &lpuart1;

zephyr,sram = &sram0;

zephyr,flash = &flash0;

zephyr,canbus = &fdcan2;

zephyr,code-partition = &slot0_partition;

};

|

The first thing to know is that the start of line 12 is the start of the

definition of a node, in this case the root (/) node. Like most

languages, everything inside the curly brackets is part of that

definition.

The /chosen node sets up some defaults. For example, line 17 says that

the node lpuart1 is the default Zephyr console. The & is used a lot

like C to grab the "address of" something else. They're called

phandles.

In this case, lpuart1 is the low power

UART.

Low power means it can function in low power mode when the low-speed

(32.768KHz) clock is in effect. It is, however, limited to 9600bps at

that time.

| leds {

compatible = "gpio-leds";

blue_led: led_0 {

gpios = <&gpioc 6 GPIO_ACTIVE_HIGH>;

label = "User LED";

};

};

|

First we set up the on-board LED, in this case, an annoying blue one.

Walking through this, line 25 creates the /leds node to contain all

the LEDs on the board. It then says it's compatible with the gpio-leds

hardware feature, and creates a specific instance /leds/led_0 that

also has an label with a different name, /leds/blue_led (line 27). On

line 28 it sets up the GPIO pins for that LED. Since the LED is attached

to pin PC6, we know that it's part of the C cluster of GPIO pins

(&gpioc), and then pin #6 in that cluster. Finally, we tell it that

the pin is considered active, when it's high. Zephyr can tell the

difference between active high and active low pins. The <> defines an

array, here with 3 elements.

Note we are referencing phandles that are defined outside of our file

and have been brought in via the earlier includes.

| pwmleds {

compatible = "pwm-leds";

blue_pwm_led {

pwms = <&pwm3 1 PWM_MSEC(20) PWM_POLARITY_NORMAL>;

};

};

|

Next, what's an LED that you can't dim? Useless, that's what!

So, as above, we explain that it's compatible with the pwm-leds

feature, and name the node /pwmleds/blue_pwm_led. We then have to set

up the timer that specifically drives the pulse-width modulated (PWM)

signal.

The hidden world of timers

This is hidden in things like Arduino, but in Zephyr and most

other embedded systems, you have to know which timers are able to be

connected to which GPIO pins. This is often considered an "alternate

function" of the pin. On STM32 there are multiple times, and each

timer can have multiple "channels". There's various restrictions on

them, but that's a topic for another time.

Here, we say this PWM is on channel 1 of timer 3, with a nominal period

of 20ms, and "normal" polarity, meaning it's active high.

| gpio_keys {

compatible = "gpio-keys";

user_button: button {

label = "User";

gpios = <&gpioc 13 GPIO_ACTIVE_LOW>;

zephyr,code = <INPUT_KEY_0>;

};

};

|

Now we define some fancy "keys". This is part of the

gpio-keys

feature, which allows you to map GPIO pins into a set of input events,

rather than just GPIO events. Think of it as mapping the keys on a

keyboard. There are other more

advanced

options for key matrices. The properties are similar to earlier, except

this button is active when it's low (pulled to ground), and then we say

that it emits 0 into the input stream when pressed.

50

51

52

53

54

55

56

57

58

59

60 | aliases {

led0 = &blue_led;

mcuboot-led0 = &blue_led;

pwm-led0 = &blue_pwm_led;

sw0 = &user_button;

watchdog0 = &iwdg;

die-temp0 = &die_temp;

volt-sensor0 = &vref;

volt-sensor1 = &vbat;

};

};

|

Here we set up a bunch of aliases that can be used to refer to things.

These work exactly like any other phandle, so referencing &led0 is the

same as referencing &blue_led.

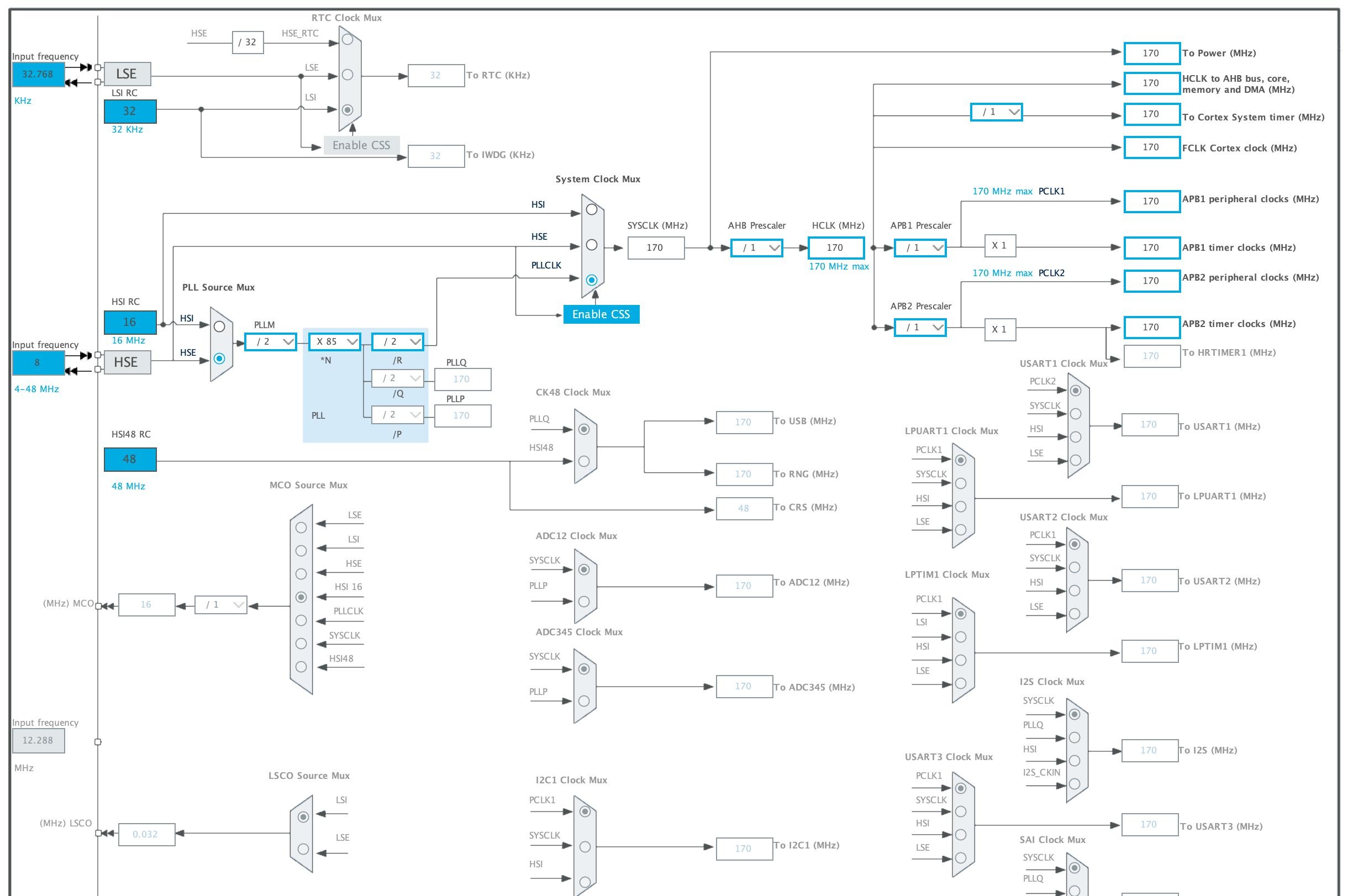

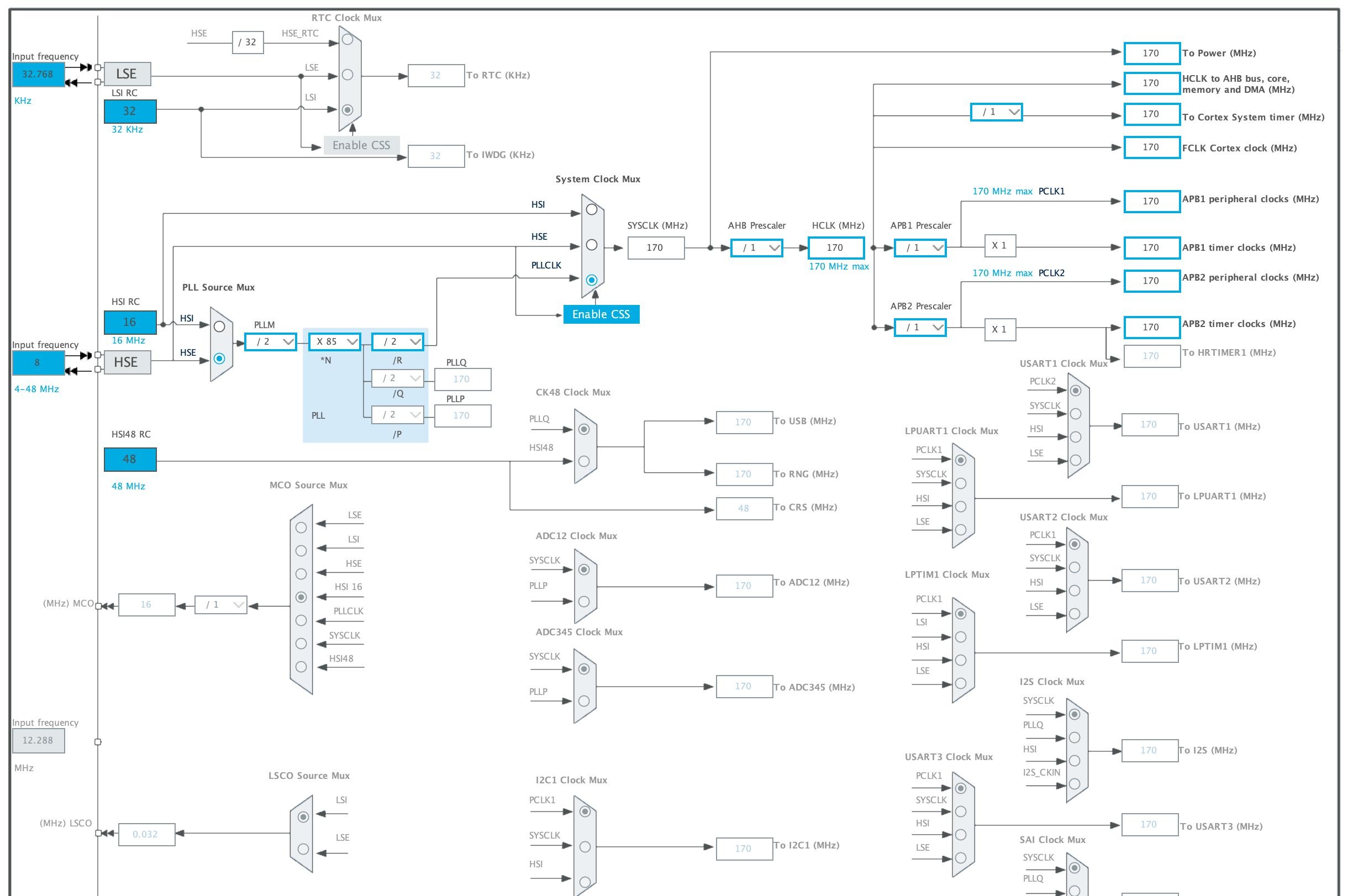

Now comes the beast of a thing .. the clock tree. This is something that

if you've never worked low-level (below Arduino, for example), you're

probably completely unfamiliar with. There are multiple clock sources,

phase-locked loops, and derivative clocks that drive everything. There's

an excellent

tutorial

on the STM32 support forum.

| &clk_lsi {

status = "okay";

};

|

Here we just tell Zephyr that the low-speed internal clock is "okay",

meaning you can use it. You'll see this notation somewhat frequently.

| &clk_hsi48 {

status = "okay";

};

|

Here we do the same thing for the high-speed internal clock, which runs

at 48MHz.

| &clk_hse {

clock-frequency = <DT_FREQ_M(8)>;

status = "okay";

};

|

Now here's where it gets interesting. Here we have to tell the system

what the high-speed

external clock is. It just gets a repeated pulse

from the crystal, but it has no idea what that frequency is, so we tell

it that it's 8MHz.

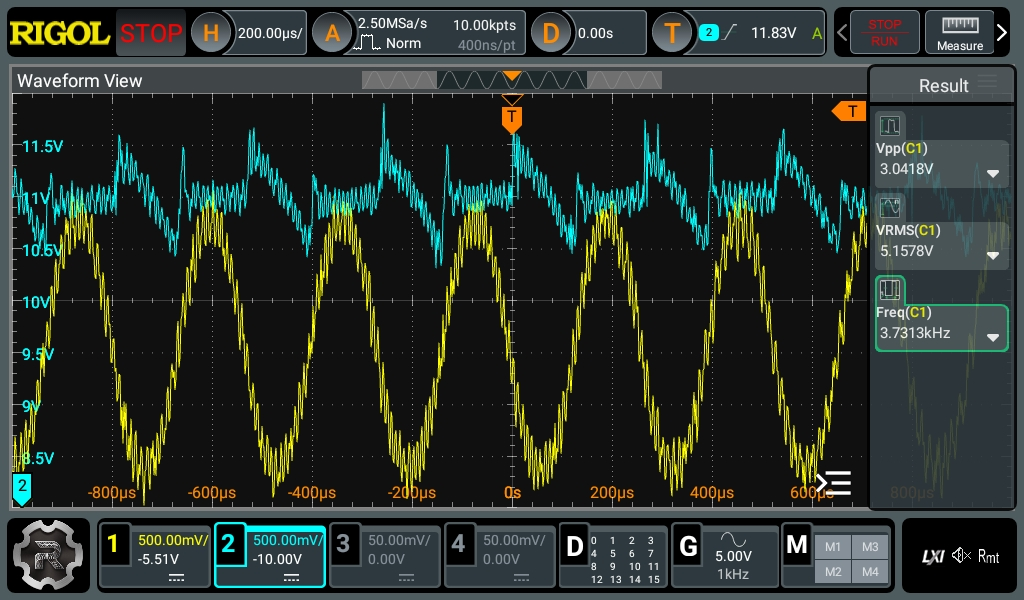

I got this wrong initially as I misread the schematic, and it resulted

in some challenges. I like to use a LED blink

program as the initial test because it sorts out

the clocks as well as GPIO, and when it was initially set to be a 1s

cycle, it was taking 3.something seconds. Something was off.

It turned out that I had both clk_hse and pll wrong. I had copied

them from another SOC which has a different target clock rate, and

different oscillator frequency. There was definitely some trial and

error to sort that out as I also had to make sure I really understood

the STM32 clock tree.

75

76

77

78

79

80

81

82

83 | &pll {

div-m = <2>;

mul-n = <85>;

div-p = <2>;

div-q = <2>;

div-r = <2>;

clocks = <&clk_hse>;

status = "okay";

};

|

One of the first things that is done is to use a phase-locked

loop to create a

derivative highly accurate clock signal from the input. We tell it that

we want to use &clk_hse we just defined as the source (there's another

separate thing going on for the low-speed clock that's out of scope

here). Then we have to provide all the multipliers and divisors that it

needs to generate the output clock, which are documented in the chip

reference manual, but also some information is in this

post.

The best way to get these is to use

STM32CubeMX

and its clock solver to get it all right.

To get an idea of how complex the clock system is, here's a quick

screenshot of the clock configuration section of the app:

| &rcc {

clocks = <&pll>;

clock-frequency = <DT_FREQ_M(170)>;

ahb-prescaler = <1>;

apb1-prescaler = <1>;

apb2-prescaler = <1>;

};

|

Here we configure the reset and clock control (RCC) circuit, which is

one of the main sources that distributes and times things across the

rest of the MCU. We tell it to get its source from the PLL, and that the

target frequency is 170MHz. We then provide any scalers needed for the

various buses inside the MCU.

Why so many knobs?

You might ask, why is this so damned complicated? The main reason is

power management. If you're worrying about power consumption, say

because you're battery powered, slower clocks use less power. A lot

less. Being able to tune clocks across the system to only use the

"minimum" clock to get the job done lets you seriously dial down the

power consumption of the MCU.

In our case, we don't really care because everything in mains-powered,

and we are only talking about milliamps. But in a battery-powered

system, you could reduce the power consumption by a factor of 5 or

more.

| zephyr_udc0: &usb {

pinctrl-0 = <&usb_dm_pa11 &usb_dp_pa12>;

pinctrl-names = "default";

status = "okay";

};

|

We now enter the heavy IO section of the devicetree, and we need to

start by talking about

pin

control.

This is a deep topic, and is also specific to the individual MCU

architecture. Diving in, every GPIO (general purpose IO) pin has an

entire little active complex circuit inside it that not only drives it

but does a huge amount of configuration. Pin control is what decides if

the pin is just a regular IO pin, or if it's using an alternate function

(AF), like ADC or DAC. It determines if it's an input or output pin, if

it's pulled up or down, or left floating. It determines whether it's an

open drain output or

configured in

push-pull. It's a

whole collection of switches, resistors, and other components to let you

plop a value in an IO register and have it all magically reconfigure.

There's a great introduction to how all this works (in Linux, but it's

very much the same in Zephyr) in

this

presentation.

Here we're creating a node usb on the phandles specifically for the

USB AF on pins PA11 and PA12 as the first (0th) configuration of pin

control, which in this case is labeled as "default" and marked as OK.

99

100

101

102

103

104

105

106

107

108

109

110

111

112 | &usart1 {

pinctrl-0 = <&usart1_tx_pc4 &usart1_rx_pc5>;

pinctrl-names = "default";

current-speed = <115200>;

status = "okay";

};

&lpuart1 {

pinctrl-0 = <&lpuart1_tx_pa2 &lpuart1_rx_pa3>;

pinctrl-1 = <&analog_pa2 &analog_pa3>;

pinctrl-names = "default", "sleep";

current-speed = <115200>;

status = "okay";

};

|

Something similar is happening here, but in the lpuart1 we have

something different. We have 2 different configurations (0, 1) with

different names (aliases basically) of "default" and "sleep". We're

saying that in the normal running mode, this is the TX and RX pins for

the low-power UART #1, but when the chip is asleep, it flips to a

regular analog I/O, which allows for easier wake-up.

| &i2c1 {

pinctrl-0 = <&i2c1_scl_pb8 &i2c1_sda_pb9>;

pinctrl-names = "default";

status = "okay";

};

|

...

| &spi1 {

pinctrl-0 = <&spi1_sck_pa5 &spi1_miso_pa6 &spi1_mosi_pa7>;

pinctrl-names = "default";

cs-gpios = <&gpiob 6 (GPIO_ACTIVE_LOW | GPIO_PULL_UP)>;

status = "okay";

};

|

Here we're defining an

SPI set of

pins. The cs-gpios defines the pin PB6 as the chip select line for the

SPI port, marks it as active when it's low, and then attaches a pull-up

resistor to it internally to hold it inactive by default.

127

128

129

130

131

132

133

134

135

136

137

138

139 | &spi2 {

pinctrl-0 = <&spi2_nss_pb12 &spi2_sck_pb13

&spi2_miso_pb14 &spi2_mosi_pb15>;

pinctrl-names = "default";

status = "okay";

};

&spi3 {

pinctrl-0 = <&spi3_nss_pa15 &spi3_sck_pc10

&spi3_miso_pc11 &spi3_mosi_pc12>;

pinctrl-names = "default";

status = "okay";

};

|

More of the same here, but without the chip select defined yet. This can

be done in the user's code.

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165 | &timers2 {

status = "okay";

pwm2: pwm {

status = "okay";

pinctrl-0 = <&tim2_ch1_pa5>;

pinctrl-names = "default";

};

};

&timers3 {

st,prescaler = <10000>;

status = "okay";

pwm3: pwm {

status = "okay";

pinctrl-0 = <&tim3_ch1_pb4>;

pinctrl-names = "default";

};

};

stm32_lp_tick_source: &lptim1 {

clocks = <&rcc STM32_CLOCK_BUS_APB1 0x80000000>,

<&rcc STM32_SRC_LSI LPTIM1_SEL(1)>;

status = "okay";

};

|

We need to set up our timers, and we configure them for use as PWM

timers as well. The st,prescaler is an STM32-specific property that

says that the timer should be "scaled" down by 1000x.

We also define a low-power tick source leveraging the low-power timer #1.

Unfortunately, I don't actually understand the clocks property and

copied it from another definition. I have no idea if it works.

| &rtc {

clocks = <&rcc STM32_CLOCK_BUS_APB1 0x00000400>,

<&rcc STM32_SRC_LSI RTC_SEL(2)>;

status = "okay";

};

|

The STM32 has a real-time clock (RTC) that keeps a time and date

running as long as it's not in the most aggressive sleep state. Again,

copied, because the clocks property escapes my understanding and

searching.

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197 | &flash0 {

partitions {

compatible = "fixed-partitions";

#address-cells = <1>;

#size-cells = <1>;

boot_partition: partition@0 {

label = "mcuboot";

reg = <0x00000000 DT_SIZE_K(34)>;

};

slot0_partition: partition@8800 {

label = "image-0";

reg = <0x00008800 DT_SIZE_K(240)>;

};

slot1_partition: partition@44800 {

label = "image-1";

reg = <0x00044800 DT_SIZE_K(234)>;

};

/* Set 4Kb of storage at the end of the 512Kb of flash */

storage_partition: partition@7f000 {

label = "storage";

reg = <0x0007f000 DT_SIZE_K(4)>;

};

};

};

|

We need to break the flash storage into a few pieces here. We define 4

partitions for the boot loader, two versions of the code, and a 4Kb

storage area that you could lay a filesystem abstraction on top of, or

just store things directly into.

199

200

201

202

203

204

205

206

207

208

209 | &iwdg {

status = "okay";

};

&rng {

status = "okay";

};

&die_temp {

status = "okay";

};

|

Just a few peripherals, the watchdog timer (iwdg), random number

generator (rng), and die temperature sensor (die_temp). We simply

mark them as available and ready.

211

212

213

214

215

216

217

218

219

220

221

222

223 | &adc1 {

pinctrl-0 = <&adc1_in1_pa0>;

pinctrl-names = "default";

st,adc-clock-source = <SYNC>;

st,adc-prescaler = <4>;

status = "okay";

};

&dac1 {

pinctrl-0 = <&dac1_out1_pa4>;

pinctrl-names = "default";

status = "okay";

};

|

We wire up pin PA0 to ADC #1 channel 1. We tie it to the APB bus clock

(st,adc-clock-source), rather than letting it be independent, and then

we scale it down by a factor of 4 (st,adc-prescaler).

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239 | &fdcan1 {

clocks = <&rcc STM32_CLOCK_BUS_APB1 0x02000000>,

<&rcc STM32_SRC_HSE FDCAN_SEL(0)>;

pinctrl-0 = <&fdcan1_rx_pa11 &fdcan1_tx_pa12>;

pinctrl-names = "default";

status = "okay";

};

&fdcan2 {

clocks = <&rcc STM32_CLOCK_BUS_APB1 0x02000000>,

<&rcc STM32_SRC_HSE FDCAN_SEL(0)>;

pinctrl-0 = <&fdcan2_rx_pb12 &fdcan2_tx_pb13>;

pinctrl-names = "default";

status = "okay";

};

|

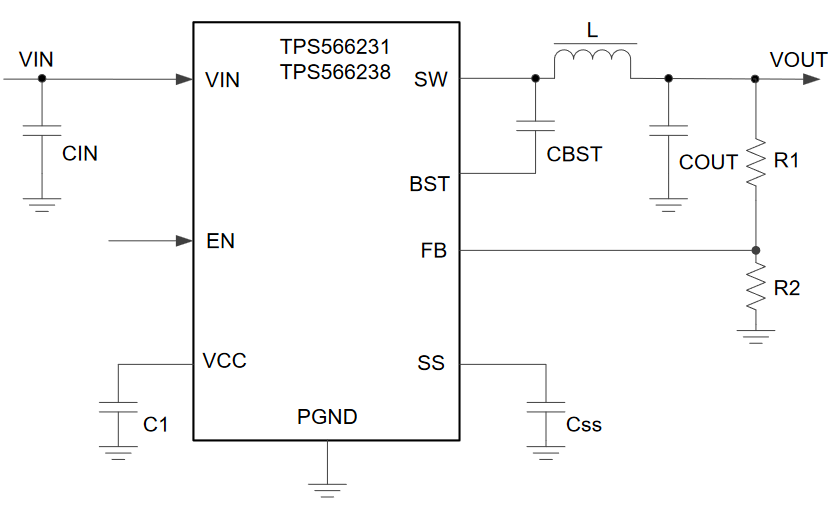

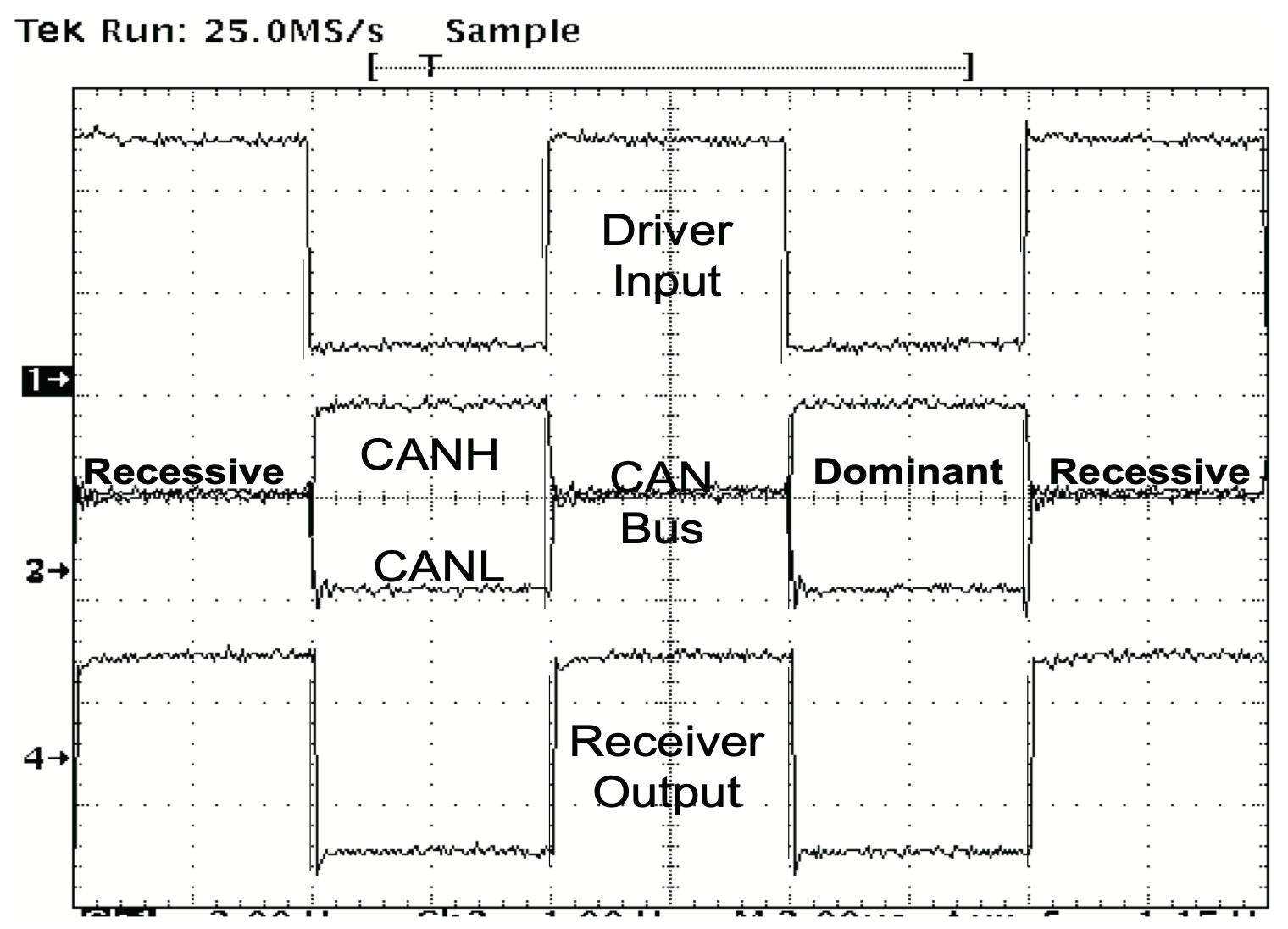

The STM3G474 has 3 CAN-FD (or is it FDCAN? I see it written both ways),

and so we configure two of them. At this point, this should be mostly

understandable.

241

242

243

244

245

246

247 | &vref {

status = "okay";

};

&vbat {

status = "okay";

};

|

And finally, we enable the VREF+ and VBAT nodes on the chip. This allows

them to be measured with the ADC.

| config BOARD_WEACT_STM32G474_LONG

select SOC_STM32G474XX

|

Here we set the base software configuration for selecting SoC and other

board and SoC related settings.

| board_runner_args(dfu-util "--device=0483:df11" "--alt=0" "--dfuse")

include(${ZEPHYR_BASE}/boards/common/dfu-util.board.cmake)

include(${ZEPHYR_BASE}/boards/common/openocd.board.cmake)

include(${ZEPHYR_BASE}/boards/common/blackmagicprobe.board.cmake)

|

Now we setup some things to make programming the board easier. You can

get the values for --device and --alt by running the dfu-util -l

when the board is plugged in and in DFU mode (for this one, that means

holding down the BOOT0 button while pressing the NRST button). You'll

get something like this:

$ dfu-util -l

dfu-util 0.11

Copyright 2005-2009 Weston Schmidt, Harald Welte and OpenMoko Inc.

Copyright 2010-2021 Tormod Volden and Stefan Schmidt

This program is Free Software and has ABSOLUTELY NO WARRANTY

Please report bugs to http://sourceforge.net/p/dfu-util/tickets/

Found DFU: [0483:df11] ver=0200, devnum=1, cfg=1, intf=0, path="1-1", alt=2, name="@OTP Memory /0x1FFF7000/01*1024 e", serial="205939885533"

Found DFU: [0483:df11] ver=0200, devnum=1, cfg=1, intf=0, path="1-1", alt=1, name="@Option Bytes /0x1FFF7800/01*048 e/0x1FFFF800/01*048 e", serial="205939885533"

Found DFU: [0483:df11] ver=0200, devnum=1, cfg=1, intf=0, path="1-1", alt=0, name="@Internal Flash /0x08000000/256*02Kg", serial="205939885533"

Looking at this we can see the vendor and device ID in brackets

([0483:df11]), and the alt targets.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 | identifier: weact_stm32g474_long

name: WeAct Studio STM32G474 Long Board

type: mcu

arch: arm

toolchain:

- zephyr

- gnuarmemb

- xtools

ram: 128

flash: 512

supported:

- nvs

- pwm

- i2c

- gpio

- usb device

- counter

- spi

- watchdog

- adc

- dac

- dma

- can

- rtc

vendor: weact

|

This metadata is used primarily by the test

runner

to help determine which parts of the test suite to run. The reason is

you could target multiple boards with different capabilities, and then

adjust both your application and the testing to meet them.

1

2

3

4

5

6

7

8

9

10

11

12 | CONFIG_CLOCK_CONTROL=y

CONFIG_PINCTRL=y

CONFIG_ARM_MPU=y

CONFIG_HW_STACK_PROTECTION=y

CONFIG_GPIO=y

CONFIG_SERIAL=y

CONFIG_UART_INTERRUPT_DRIVEN=y

CONFIG_CONSOLE=y

CONFIG_UART_CONSOLE=y

|

Finally, we set some default Kconfig settings for every project that

they can override. You can learn more about each of these, although I

think they're mostly self-evident, from this search

interface.

I ran into a few problems along the way and have a few open questions.

- As mentioned earlier, the clock tree was the hardest

part that I ran into. This is also why I like an LED blink script to

test the board with. It's the simplest thing to run, but it exposes

timing issues quite quickly. You might not find a small error, but

you'll definitely find most of them.

- I still don't really understand a lot of the phandles for things like

clocks. This is just a complex topic, and my search foo isn't finding

the information I need to grok it. I'll get there eventually.

- It's unclear to me how you would start with a clean slate. Definitely

starting from a similar board helped enormously.

- Eventually, I want to figure out how to add a new SOC. They're also

defined through the device tree paradigm.

I will be putting this up on Github at some point, but need to write

some documentation first, and make sure that I've shaken it out some,

before I subject the world to it. My intention is to submit it to the

Zephyr project for inclusion in future releases.

Posted on Github

I have posted this on

Github, and it's

been renamed as the core board since it turns out both forms of

the board have the same pinouts just arranged slightly differently.

To do is cleaning it up and submitting it to the Zephyr project.

Here's the blink script that I used.

| #include <stdio.h>

#include <stdlib.h>

#include <zephyr/drivers/gpio.h>

#include <zephyr/drivers/uart.h>

#include <zephyr/kernel.h>

#include <zephyr/sys/printk.h>

#include <zephyr/usb/usb_device.h>

|

Just normal includes to get access to everything.

| /* The devicetree node identifier for the "led0" alias. */

#define LED0_NODE DT_ALIAS(led0)

/*

* A build error on this line means your board is unsupported.

* See the sample documentation for information on how to fix this.

*/

static const struct gpio_dt_spec led = GPIO_DT_SPEC_GET(LED0_NODE, gpios);

|

Here's where all that device tree work comes into play. We first resolve

the led0 alias, and then we get the GPIO spec for it. This abstraction

means that you can have a bunch of different boards with slightly

different wiring that don't require any software changes. For many uses,

it is unfortuantely, maybe an abstraction that obscures how things work.

I'm definitely of a mixed mood about it.

25

26

27

28

29

30

31

32

33

34

35

36

37 | int main(void)

{

int ret;

int sleep_ms;

if (!gpio_is_ready_dt(&led)) {

return 0;

}

ret = gpio_pin_configure_dt(&led, GPIO_OUTPUT_ACTIVE);

if (ret < 0) {

return 0;

}

|

As befits an embedded system, there's no parameters passed to main. I

mean, where would they come from?

We then make sure that there's a GPIO pin attached to the led

variable, and then configure it to be an output pin.

| ret = usb_enable(NULL);

printk("usb_enable: %i", ret);

|

Here we enable the USB functionality. I ran into some issues here,

because according to the docs, this should return 0 on success, and

something negative on failure. But I got negative values no matter what,

and yet the USB was working. On the heap of things to dig into more.

I had originally wanted to loop here to wait until the console is

attached. For that, I just use

minicom, and it's executed on

my M1 Macbook Air as minicom -D /dev/tty.usbmodem1101 -b 115200. Not

really sure that the baud rate matters, but I used it anyway.

42

43

44

45

46

47

48

49

50

51

52

53

54 | while (1) {

ret = gpio_pin_toggle_dt(&led);

if (ret < 0) {

return 0;

}

printk("LED state: %s\n", gpio_pin_get(led.port, led.pin) ? "ON" : "OFF");

// 1000ms = 1s

k_msleep(1000);

}

return 0;

}

|

Finally, we throw the program into an infinite loop and toggle the pin

off and on, printing out the current state of the pin and sleeping 1

second, leading to 1 second on and 1 second off. The program is

marginally more complicated than an Arduino sketch, but that's largely

because Arduino's framework hides many things from you. Up to a point,

this is a huge win, until it's not. For my overly complicated project, I

wanted to have it all exposed. I'll be diving into more advanced

features of Zephyr later like pub/sub, threading, sensor framework, etc.

And with that, we're kinda done? Somewhat done? The magic

smoke didn't come out of the

chip, at least!

When last we talked, I was talking about a modular base board built

around an STM32H5, but I realized that there was another alternative ...

build it around an existing board. So, that's my plan now. This removes

a lot of design work, yes, but at least for the initial design, it lets

me focus on some other things. I've chosen to use a board from WeAct

Studio. These are the people behind the famous Blue Pill and Black Pill

STM32 boards. They also make one built around an

When last we talked, I was talking about a modular base board built

around an STM32H5, but I realized that there was another alternative ...

build it around an existing board. So, that's my plan now. This removes

a lot of design work, yes, but at least for the initial design, it lets

me focus on some other things. I've chosen to use a board from WeAct

Studio. These are the people behind the famous Blue Pill and Black Pill

STM32 boards. They also make one built around an